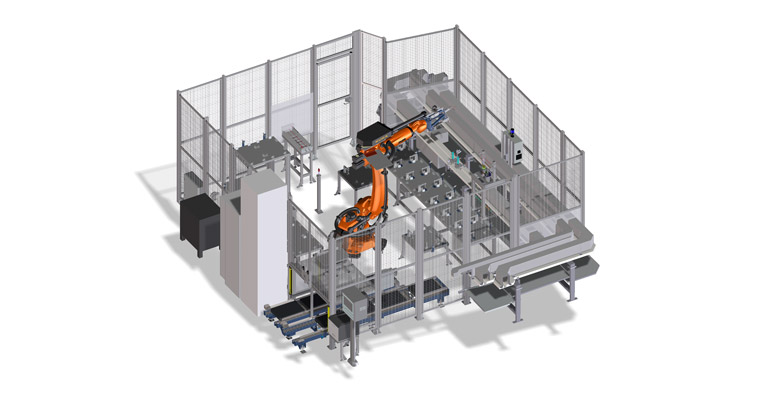

Assembly and automation systems

Simple processes in complex machinery

Assembly systems are complex and interlinked machines that represent an essential part of the value chain in the manufacture of products. This is where the most important aspects of automation come together in one system.

As a system manufacturer and specialist in assembly automation, we offer all important components. Including:

- Interlinking

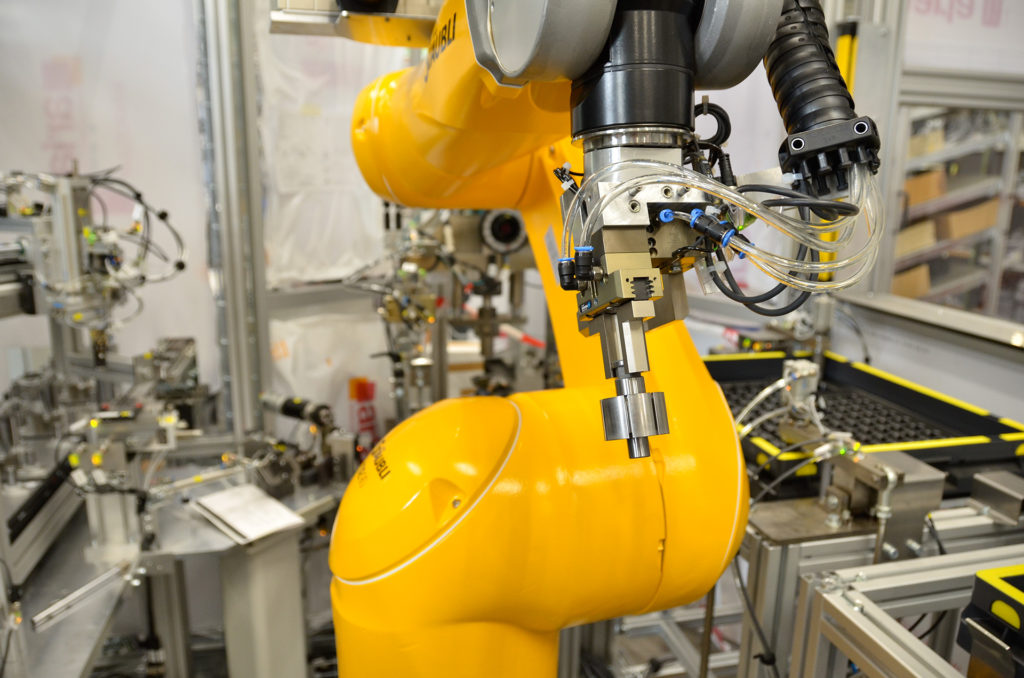

(e.g. robots, belt and chain systems, cycle systems, axis portals) - Handling

(e.g. pneumatic and axis handling, robots) - Assembly

(welding, joining, gluing, screwing, plugging, dosing) - Measuring

(e.g. paths, length and angle, force and moment, color and brightness, volume, resistance, and impedance) - Testing

(e.g. shape and position, tightness and flow, drag torque, tooth flank play, switching point, opening and closing pressure) - Forming

(caulking, crimping) - Labeling

(laser, ink, sponge, needle and scratch markers, stickers) - Data Management

(e.g., traceability, Industry 4.0, interface communication)

Based on your product and the planned production volume, we work with you to determine what individual modules should be combined, the process design, and thus the machine concept. We will also figure out the resulting degree of automation and thus the required cycle time.

Our goal: To provide you with the most economical overall solution.

Let us advise you on assembly systems in your company.

Kraft

Weg

Drehmoment

Drehwinkel

Stromstärke

Spannung

elektr. Widerstand

Schaltzeit

Druck

Durchfluss

Dichtheit

Nass- und Trockenprüfung

Sauber- und Reinraum

Vakuum und Überdruck

Körperschall

Leichtlauf

Beschädigung

Lorem ipsum

dolor sit amet

consetetur

sadipscing

Get advice now

Do you have any questions? Our friendly sales staff is here to help!

+49 33439 674-175

Vertrieb@mp-bln.de